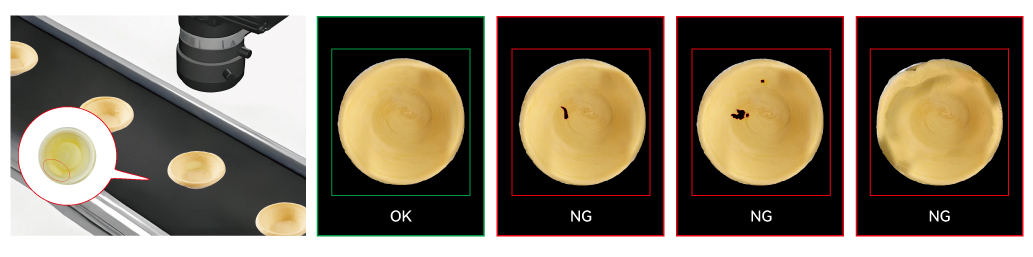

Johnson Smart intelligent frozen tart crust AI visual appearance defect detection solution breaks through traditional visual technology and adopts AI algorithms to achieve rapid deep learning and iteration through system adaptation and customization. Combining artificial intelligence technology with machine vision technology, the system can recognize, analyze and understand the content in the image, identify the appearance of the tart crust and locate defects, and realize the detection of product appearance quality. Defective products are automatically picked up and removed to the designated area by robots, avoiding possible misjudgments and missed judgments in manual sorting, and ensuring the stability and consistency of product quality.

Detection accuracy

The AI visual inspection system uses dynamic flying camera technology to detect defects as small as 0.5mm on the surface of egg tarts. It maintains a detection rhythm of 1s/pcs for defects such as breakage, bubbles, hair, foreign matter, and cracks while the conveyor belt is running continuously. The defect contour features can be further filtered by adjusting the NG judgment index.

Solution Advantages

■ Build a universal model, use AI algorithm instead of traditional algorithm, complete the consistency preprocessing of tart crust, and realize the sharing of universal model.

■ Improve the detection efficiency, reduce the dependence on manual work, and ensure the stability and consistency of tart crust quality.

■ It can timely detect whether the tart crust has black spots, damage, blistering, foreign matter and other problems, helping enterprises reduce customer complaints

■ Use Jiansong intelligent patented picking technology.

Program Features

■ Identify complex defects: meet the defect detection requirements of production lines under high-speed production;

■ Improve detection accuracy: AI autonomously learns, accurately identifies and defines more than dozens of defect types;

■ Improve detection accuracy: continuously collect defect samples, continuously iterate autonomously, and improve detection efficiency;

■ General large model: establish a defect database, accurately label defect categories, and accumulate general large models;