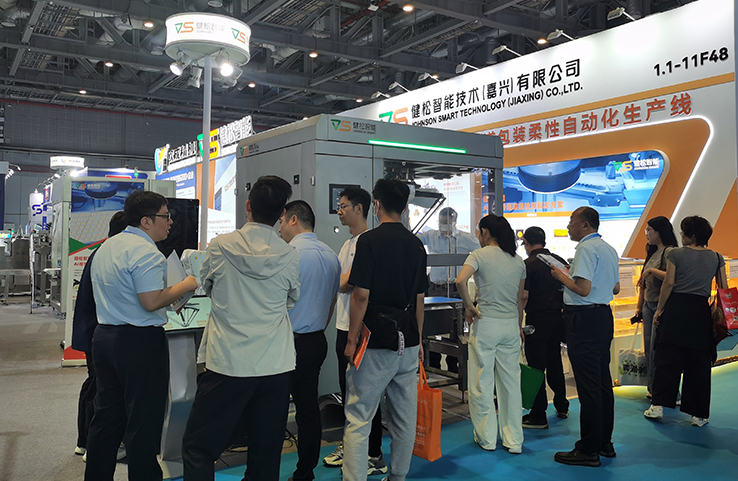

On May 19, 2025, the four-day 27th China International Bakery Exhibition (Bakery China) came to a successful conclusion at the National Exhibition and Convention Center (Shanghai). Jiansong Intelligence ended this meaningful exhibition journey with the perfect integration of innovative technology and intelligent manufacturing.

|

|

|

|

|

|

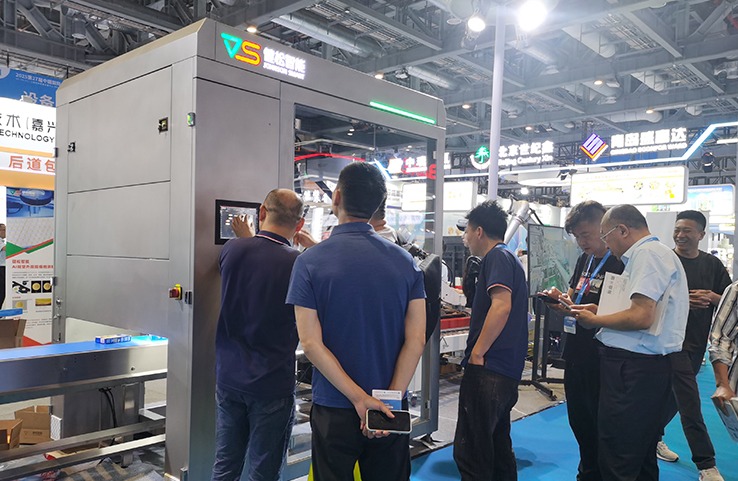

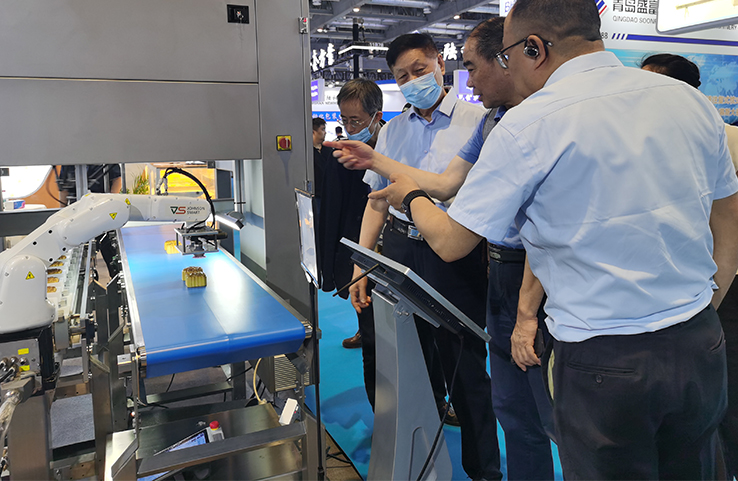

In this industry event, Johnson Smart took "Back-end Flexible Packaging Automated Production Line" as the core theme, and made a stunning appearance with a full-scenario solution matrix consisting of cutting-edge innovative achievements such as parallel robots, collaborative palletizing robots, SCARA robots, and six-axis robots.。

|

|

|

|

|

|

Through the dynamic production line real-life demonstration, the technological breakthroughs and service capabilities of manufacturing companies in the field of food packaging automation are fully presented. It not only deeply interprets the innovative concepts of flexible manufacturing and smart factories, but also demonstrates the outstanding style of "China Smart Manufacturing" with precise and efficient intelligent and flexible solutions.

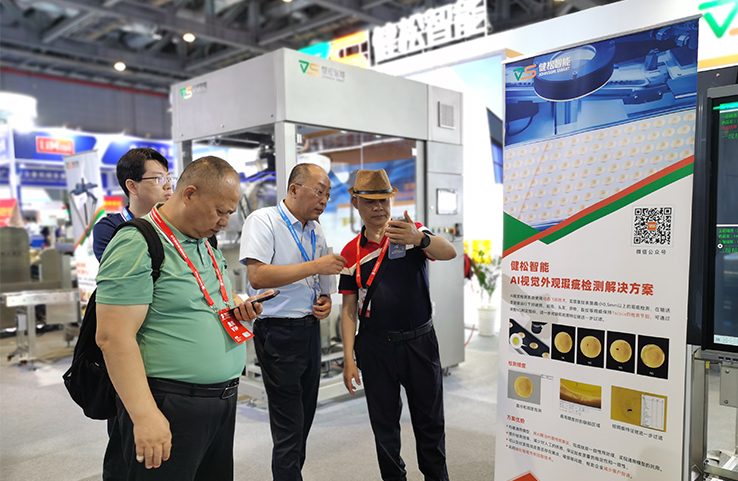

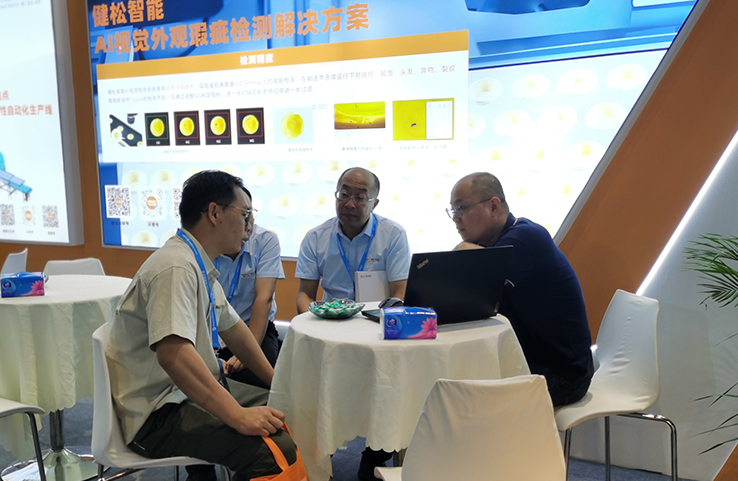

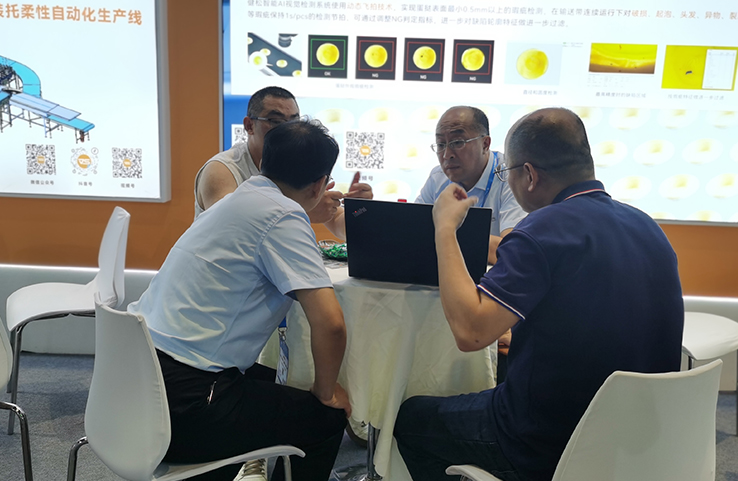

AI Visual and Robotic Unit for Appearance Defect Detection

Johnson Smart tart crust AI visual inspection system uses dynamic flying camera technology to detect defects on the surface of egg tarts with a minimum size of 0.2mm or more. It maintains a detection rhythm of 5s/pcs for defects such as breakage, blistering, hair, foreign matter, and cracks while the conveyor belt is running continuously. The defect contour features can be further filtered by adjusting the NG judgment index.

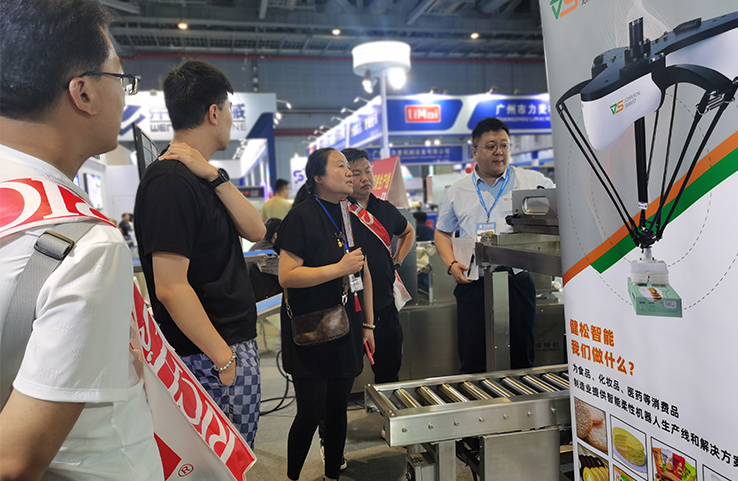

Robotic Unit for Tray Loading

Based on the integration of SCARA robots and Delta parallel robots, the flexible automation system for palletizing and loading can accurately perform processes such as material positioning, multi-specification product placement, flexible loading and high-speed sorting, and supports multi-variety mixed-line production modes. It can independently set different product specifications, packaging quantities and arrangement methods.

Robotic Unit for Packing and Palletizing

The robotic packing and palletizing system consists of a flexible robotic packing unit, a collaborative robotic palletizing workstation, and a carton opening and sealing machine, realizing a fully automated assembly line for unpacking, packing, sealing, and palletizing. The flexible robotic packing unit meets the needs of mixed-code packing of multiple specifications and different sizes in industries such as food, medicine, daily chemicals, 3C electronics, and e-commerce logistics. The robot can automatically identify, grab, and stack products.

Robotic Production Line for making Thousand Layer Cake

The automated production line for crepe cakes is specially developed for the flexible production of 6-12 inch crepe cakes, realizing the automation of the entire process from crust making to finished product packaging. The robot unit accurately picks up and stacks the crust, and the back-end cream coating machine automatically completes the cream filling and even coating of the sandwich layer. The entire production process does not require human intervention.

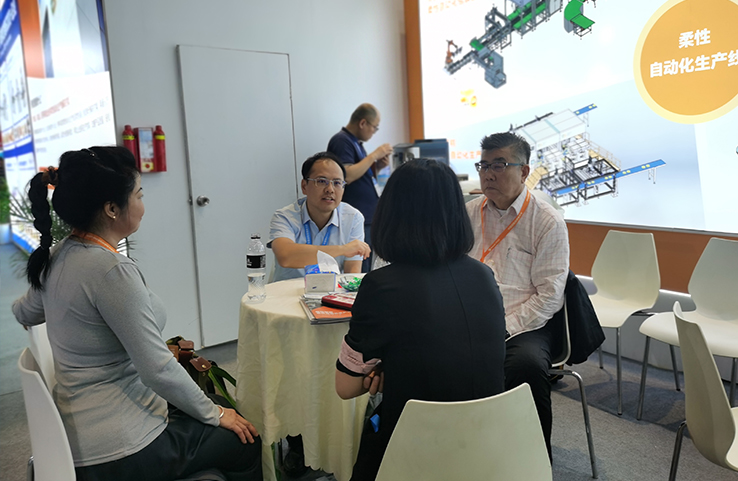

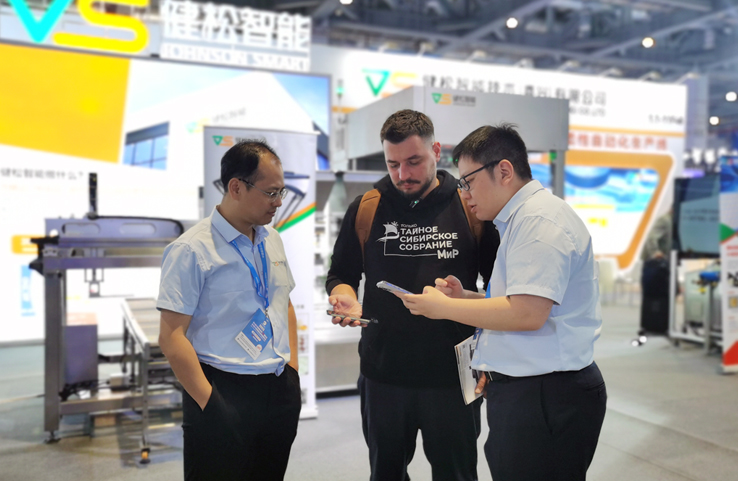

At the exhibition, Jiansong Intelligence became popular with its display of various industry applications, attracting many exhibitors to communicate and consult.

|

|

|

|

|

|