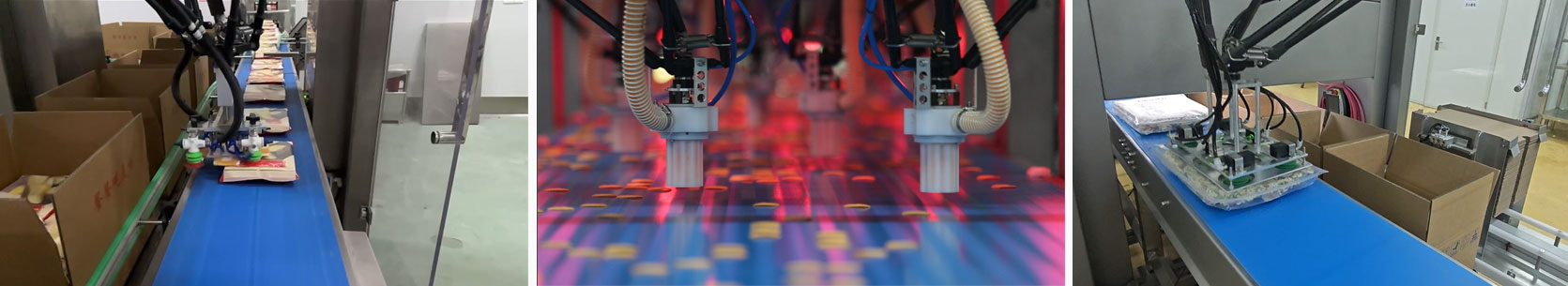

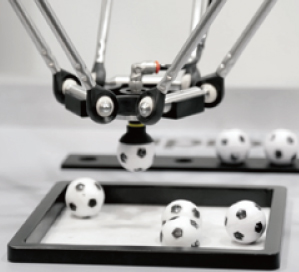

Automation is a new trend in the field of packaging that is developing rapidly. Jiansong Intelligent has been providing food manufacturers with fully automatic flexible packaging production lines and flexible robots. Our product portfolio includes single machines and complete lines, which can be used for primary and secondary packaging of foods (such as snack foods, biscuits, baked foods, frozen foods and dairy products). Flexibility, gentleness and speed are the key elements of food packaging, and the Delta robot is an ideal object picking device that can be used for object picking and placement, assembly, material handling, etc. At the same time, it can also be perfectly applied to the visual recognition of objects of different shapes (even objects in motion). Thanks to the robot's integrated vision system, the Delta robot can realize different types of distributed object picking processes.

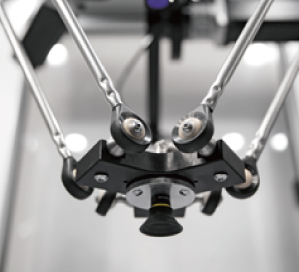

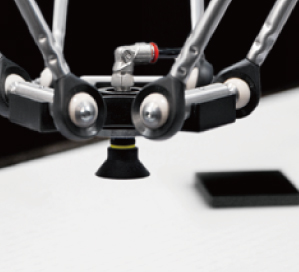

Delta robots are often used in automated food packaging production lines. The IP69 protection design of the robot and its surroundings, as well as the use of titanium alloy and stainless steel DIN1.4404 (316L) design, are very suitable for baked food production lines. They have the characteristics of high rigidity, balanced force, strong load-bearing capacity, small error, high precision, small self-weight load ratio, simple structure, good power performance, fast movement, easy control, quietness and low maintenance. For the tray, box, case or shrink film packaging of various varieties and specifications of baked foods and snack foods, Delta robot sorting shows its powerful flexibility. The robot gripper can adopt vacuum suction cup type, splint type, finger pull-out type and other structural forms to ensure the rapid grasping and movement of various packaging forms.

System Characteristics:

+ Remote control

+ Suitable for all operating systems

+ Widely used, high precision

+ Low total cost

+ Simple to operate, easy to clean

+ Low fault rate, lifetime maintenance

Learn more about our wide range of customized line and automation solutions as well as industry-specific concepts that equip you for emerging market demands.

The flexible, automated production line for tart shell case packing and palletizing provides a fully automated solution for the entire process, from tart shell case packing, weighing and testing, wrapping, to palletizing. An intelligent visi

The food packaging solution for Tetra Pak/Peregrine/Ecolean packaging consists of 8 sets of flexible robot manufacturing units + 6 sets of standard flexible manufacturing units. It has excellent flexibility and can accurately control the pos

Johnson Smart The AI visual inspection system for egg tart crust uses dynamic flying camera technology to detect defects on the surface of egg tarts with a minimum size of 0.2mm or more. It maintains a detection rhythm of 5s/pcs for de

Based on the integration of SCARA robots and Delta parallel robots, the flexible automation system for palletizing and loading can accurately perform processes such as material positioning, multi-specification product placement, flexible loa

Johnson Smart The robotic packing and palletizing system consists of a flexible robotic packing unit, a collaborative robotic palletizing workstation, and a carton opening and sealing machine, realizing a fully automated assembly line for un

This solution is suitable for the flexible production needs of mooncakes Program composition:2 sets of flexible robot manufacturing units Unit production capacity:10000 per hour Program benefits:Replace 20 labour (10 labour per shift,